Location: Home >Ferrosilicon

Ferrosilicon

Ferrosilicon is an alloy of iron and silicon. Ferrosilicon is made of iron silicon alloy made of cok

- 1:Ferrosilicon is an indispensable deoxidizer in the steelmaking industry

- 2:Used as inoculant and spheroidizer in the cast iron industry

- 3:Used as reducing agent in ferroalloy production

-

Packaging can be customized according to customer needs

-

Email: cathy@hncczz.com

■ detail intruduction

Ferrosilicon is an alloy of iron and silicon. Ferrosilicon is made of iron silicon alloy made of coke, steel chips, quartz (or silica) as raw material and smelted by electric furnace. Because silicon and oxygen are easy to combine into silicon dioxide, so ferro silicon is often used as deoxidizer in steelmaking. At the same time, due to the release of a lot of heat when SiO2 is generated, it is beneficial to improve the temperature of molten steel at the same time of deoxidation. At the same time, ferrosilicon can also be used as an alloying element additive, widely used in low alloy structural steel, spring steel, bearing steel, heat resistant steel and electrical silicon steel, ferrosilicon in ferroalloy production and chemical industry, often used as a reducing agent.

Iron silicon supply grain size:0-1mm,1-3mm,3-10mm,10-50mm,50-100mmOr custom.

Ferrosilicon is widely used in steel industry, casting industry and other industrial production.

Ferrosilicon is an indispensable deoxidizer in steelmaking industry. In torch steel, ferrosilicon is used for precipitation and diffusion deoxidation. Billet iron is also used as an alloying agent in steelmaking. Adding a certain amount of silicon to steel can significantly improve the strength, hardness and elasticity of steel, improve the permeability of steel, and reduce the hysteresis loss of transformer steel. General steel contains 0.15%-0.35% silicon, structural steel 0.40%-1.75% silicon, tool steel 0.30%-1.80% silicon, spring steel 0.40%-2.80% silicon, stainless acid-resistant steel 3.40%-4.00% silicon, heat-resistant steel 1.00%-3.00% silicon, Silicon steel contains silicon 2% ~ 3% or higher.

High silicon ferrosilicon or siliceous alloys are used as reducing agents in the ferroalloy industry to produce low carbon ferroalloys. Adding ferrosilicon into cast iron can be used as inoculant of nodular cast iron, and can prevent the formation of carbide, promote the precipitation and spheroidization of graphite, and improve the properties of cast iron.

In addition, ferrosilicon powder can be used as suspension phase in the mineral processing industry, as electrode coating in electrode manufacturing; High silicon ferrosilicon can be used to prepare semiconductor pure silicon in the electrical industry, and can be used to manufacture silicone in the chemical industry.

In the steelmaking industry, about 3 ~ 5kg 75%ferrosilicon is consumed per ton of steel produced.

Ferrosilicon component content:

Brand | Chemical composition(%) | |||||||

Si | Al | Ca | Mn | Cr | P | S | C | |

The scope of | < | |||||||

FeSi75Al0.5-A | 74.0-80.0 | 0.5 | 1.0 | 0.4 | 0.3 | 0.035 | 0.02 | 0.1 |

FeSi75Al0.5-B | 72.0-80.0 | 0.5 | 1.0 | 0.5 | 0.5 | 0.04 | 0.02 | 0.2 |

FeSi75Al1.0-A | 74.0-80.0 | 1.0 | 1.0 | 0.4 | 0.3 | 0.035 | 0.02 | 0.1 |

FeSi75Al1.0-B | 72.0-80.0 | 1.0 | 1.0 | 0.5 | 0.5 | 0.04 | 0.02 | 0.2 |

FeSi75Al1.5-A | 74.0-80.0 | 1.5 | 1.0 | 0.4 | 0.3 | 0.035 | 0.02 | 0.1 |

FeSi75Al1.5-B | 72.0-80.0 | 1.5 | 1.0 | 0.5 | 0.5 | 0.04 | 0.02 | 0.2 |

FeSi75Al2.0-A | 74.0-80.0 | 2.0 | 1.0 | 0.4 | 0.3 | 0.035 | 0.02 | 0.1 |

FeSi75Al2.0-B | 74.0-80.0 | 2.0 | 1.0 | 0.4 | 0.3 | 0.04 | 0.02 | 0.1 |

FeSi75Al2.0-C | 72.0-80.0 | 2.0 | 0.5 | 0.5 | 0.04 | 0.02 | 0.2 | |

FeSi75Al-A | 74.0-80.0 | 0.4 | 0.3 | 0.035 | 0.02 | 0.1 | ||

FeSi75Al-B | 74.0-80.0 | 0.4 | 0.3 | 0.04 | 0.02 | 0.1 | ||

FeSi75Al-C | 72.0-80.0 | 0.5 | 0.5 | 0.04 | 0.02 | 0.2 | ||

FeSi65 | 65.0-<72.0 | 0.6 | 0.5 | 0.04 | 0.02 | |||

FeSi45 | 40.0-47.0 | 0.7 | 0.5 | 0.04 | 0.02 | |||

The use of ferrosilicon:

(1)Ferrosiliconisanindispensabledeoxidizerinsteelmakingindustry.Insteelmaking,ferrosiliconisusedforprecipitationanddiffusiondeoxidation.Billetironisalsousedasanalloyingagentinsteelmaking.

(2)Usedasinoculantandspheroidizingagentincastironindustry.Intheproductionofductileiron,ferrosilicon75isanimportantinoculant(helpingtoprecipitategraphite)andspheroidizingagent.

(3)Usedasreducingagentinferroalloyproduction.Notonlyisthechemicalaffinitybetweensiliconandoxygenveryhigh,butthecarboncontentofhighsiliconferrosiliconisverylow.Therefore,highsiliconferrosilicon(orsiliceousalloy)isacommonlyusedreducingagentintheproductionoflowcarbonferroalloyinferroalloyindustry.

(4)75ferrosiliconisoftenusedinthehightemperaturesmeltingprocessofmagnesiuminpijiangprocess,replacingmagnesiuminCAo.MGO,andconsumingabout1.2tonsofferrosiliconforeverytonofmagnesiummetal,whichplaysagreatroleintheproductionofmagnesiummetal.

(5)Useinotherways.Pulverizedoratomizedferrosiliconpowdercanbeusedassuspendedphaseinmineralprocessingindustry.

(6)Canbeusedaselectrodecoatinginelectrodemanufacturing.Highsiliconferrosiliconinthechemicalindustrycanbeusedtomanufacturesiliconeandotherproducts.

72ferrosilicon/75ferrosiliconpackaging:

Tonbagpackaging,1000kg/bag.

Productspecificationscanbecustomizedaccordingtocustomerrequirements.

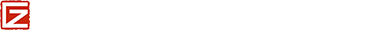

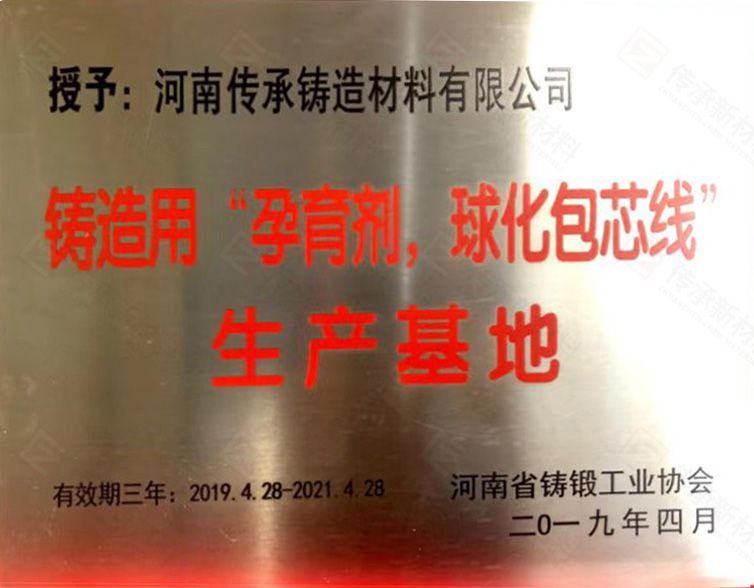

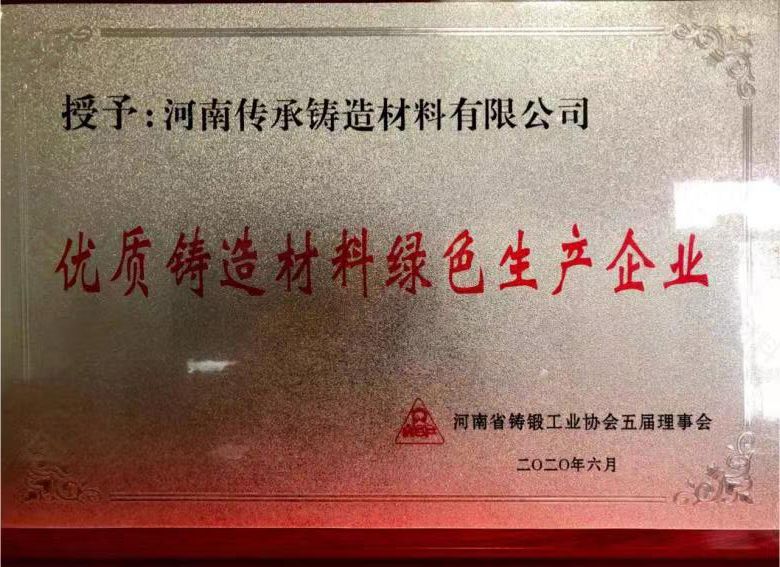

■ Enterprise overview

■ Recommended Products

■ Message/Inquiry

Remarks: Confirm the sample index, model weight and delivery address