Carburant

Carburizer (carbon) is an indispensable additive in iron and steel smelting, its use can save a lot

- 1:Increase the carbon content in the steel and reduce the sulfur content in the steel

- 2:Steel-making carbonization and the production of ductile iron with a large amount of scrap steel, gray iron castings are ideal carbonizing materials

-

Packaging can be customized according to customer needs

-

Email: cathy@hncczz.com

■ detail intruduction

Carburizer (carbon) is an indispensable additive in iron and steel smelting, its use can save a lot of iron ore use, while increasing the use of scrap steel, scrap iron, reduce production costs, save non-renewable resources. In other words, the use of carburizer, not only can increase the carbon content in steel, but also can reduce the sulfur content in steel, is a multi-purpose additive.

There are many kinds of raw materials of carburizer, the production process is also different, there are wood carbon, coal carbon, coke, graphite, etc., which are classified under a variety of small types. High quality carburizer generally refers to the carburizer after graphitization. Under high temperature conditions, the arrangement of carbon atoms is the microscopic form of graphite, so it is called graphitization. Graphitization can reduce the content of impurities in the carburizer, improve the carbon content of the carburizer, reduce the sulfur content. Carburizer used in casting, can greatly increase the amount of scrap, reduce the amount of pig iron or without pig iron.

This product is made of high purity and high quality carbon as raw material by high temperature graphitization calcination, with complete varieties and specifications, which can meet the needs of different customers. It is the most ideal carburizing material for steel making and nodular iron and gray iron castings produced by a large number of scrap steel.

1. Brand and physical and chemical indicators

Physicochemical indexes | Fixed carbon | volatile matter | Ash specification | Sulfur | Moisture | Product feature | Remark |

model | C% | V.m% | A.S.H% | S% | Mols% | ||

C-1 | ≧98 | <0.5 | <0.5 | <0.05 | <0.5 | Highcarbon, low sulfur, less impurity, high absorption rate | Ductile iron |

C-2 | ≧93 | <1.2 | <3.0 | <0.1 | <0.5 | High carbon, low sulfur, good carbon absorption effect | Ductile iron, steelmaking |

C-3 | ≧85 | <1.3 | <3.5 | <0.2 | <0.5 | Low price, stable composition, good absorption effect | Ductile iron, steelmaking |

C-4 | ≧95 | <1.0 | <1.5 | <2.0 | <0.5 | The carbon and sulfur are high, and the effect of carbon and sulfur is good | Gray pig iron |

2. Particle size

Furnace input method

Carburizer is suitable for smelting in induction furnace, but the specific use is not the same according to the process requirements.

(1)In the medium frequency electric furnace smelting using carburizer, according to the ratio or carbon equivalent requirements with the material added to the furnace in the lower part, the recovery rate can reach more than 95%;

(2)If the lack of carbon adjustment, the first play net furnace slag, plus carburant, by raising the temperature of molten iron, or artificial electromagnetic stirring to dissolve carbon absorption, recovery rate is around 90%, if the low-temperature carbonization process, namely melt furnace charge only a part of molten iron liquid under the condition of low temperature, all recarburizer one-time in liquid iron, At the same time, it is pressed into liquid iron with solid charge so as not to expose the surface of liquid iron. The carburization of liquid iron can reach more than 1.0%.

Carburization outside the furnace

(1)Graphite powder is sprayed inside the bagGraphite powder is used as carburizer, and the injection amount is 40kg/t, which is expected to increase the carbon content of liquid iron from 2% to 3%. With the increasing of the carbon content of molten iron, the utilization rate of carbon decreased. The temperature of molten iron before carbonization was 1600℃, and the average temperature after carbonization was 1299℃. Graphite powder carburization, generally using nitrogen as a carrier, but in industrial production conditions, with compressed air is more convenient, and the oxygen combustion in compressed air produces CO, chemical reaction heat can compensate for part of the temperature drop, and CO reduction atmosphere to improve the effect of carburization.

(2)Carburizing agent is used when iron is produced

Can put 100-300 mesh graphite powder carburizer into the bag,or from the iron tank with the flow into, out of the liquid iron after full stirring,dissolve and absorb as much carbon as possible,the carbon recovery rate is around 50%.

Product specifications can be customized according to customer requirements

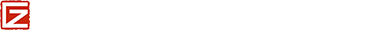

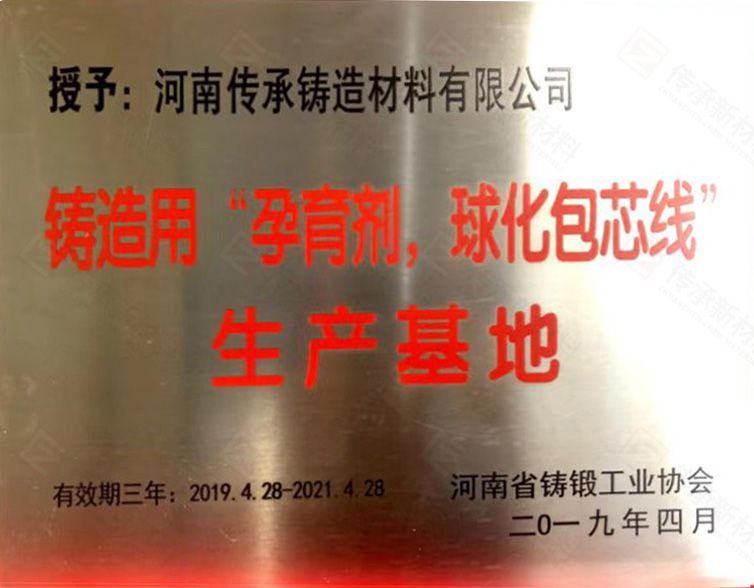

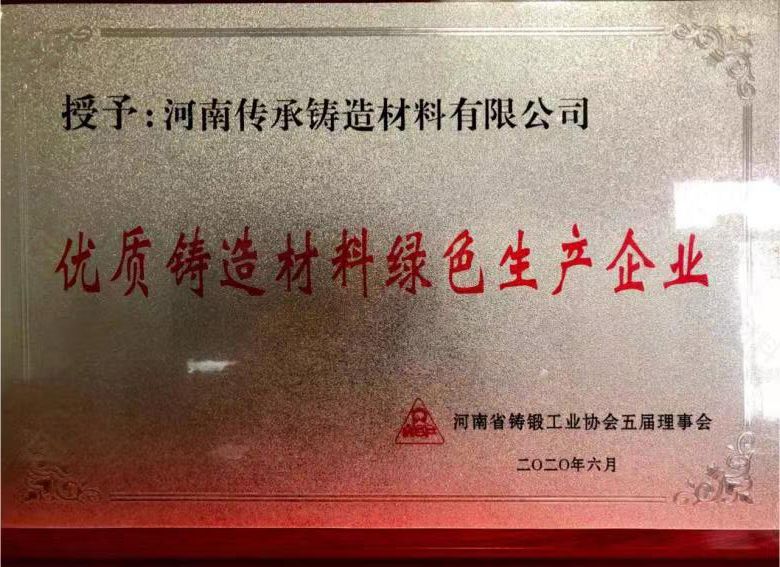

■ Enterprise overview

■ Recommended Products

■ Message/Inquiry

Remarks: Confirm the sample index, model weight and delivery address